EGCS “Scrubber” Corrosion

Exhaust Gas Cleaning Systems (EGCS) – also commonly known as “scrubbers” – have been installed on thousands of marine vessels worldwide and still, more are being fitted today. This is in order to comply with the IMO 2020 Sulphur Cap.

As one might expect with a recent innovation (within the marine sector), there have been some early issues – including EGCS corrosion. The scrubber discharge water, that contains the pollutants it has filtered, is acidic and can therefore be highly corrosive. The effects of the acidic nature of the corrosive scrubber wash water on the integrity of the ship is also aggravated by high temperatures of exhaust gases.

It is now firmly established within the marine industry that the integrity of the scrubber and associated pipework (such as the SOx scrubber discharge water line) need to be regularly checked for signs of corrosion. The two areas of particular interest and concern for vessels are the scrubber discharge outlet, the overboard pipe and adjacent plating.

Ultrasonic Testing (UT) with a thickness meter is a simple, inexpensive and reliable method to proactively engage with a program of preventative maintenance on scrubbers. Many companies around the globe are already choosing to use Cygnus thickness meters on their vessels – as part of routine scrubber integrity checks.

Cygnus Instruments was very much born in to the marine industry; our first gauges were designed 40 years ago specifically for hull inspection work. As a result of this history and rich experience, we are the experts. Our MK5 units are all purpose-designed for a tough life on board a ship: they are waterproof (IP67), drop proof and shock proof (US MIL STD 810G standard). Readings taken can be logged and uploaded to simple software in order to be referred to later; and this also makes wall thinning and corrosion easily monitored over time – any issues can be caught and addressed early.

Cygnus’ range of thickness meters all read through coatings of up to 0.4 inch (20mm) thick – which means there is no need to remove any of the important (and expensive) protective coatings or epoxy that protect against (external) scrubber corrosion. And, for heavily corroded metals where there is a thin or no coating left, Cygnus PLUS gauges incorporating Echo-Echo and Single-Echo measuring modes coupled with the Measurement Stability Indicator (MSI™) will give you the quick, accurate and reliable readings you need and that you can trust.

For oil & gas tankers, Cygnus 1 Ex thickness gauge has been the popular choice for scrubber inspections. This is due to the gauge being certified to ATEX, IECEx, UKEX for Zone 0 and NRTL for Class 1, Division 1.

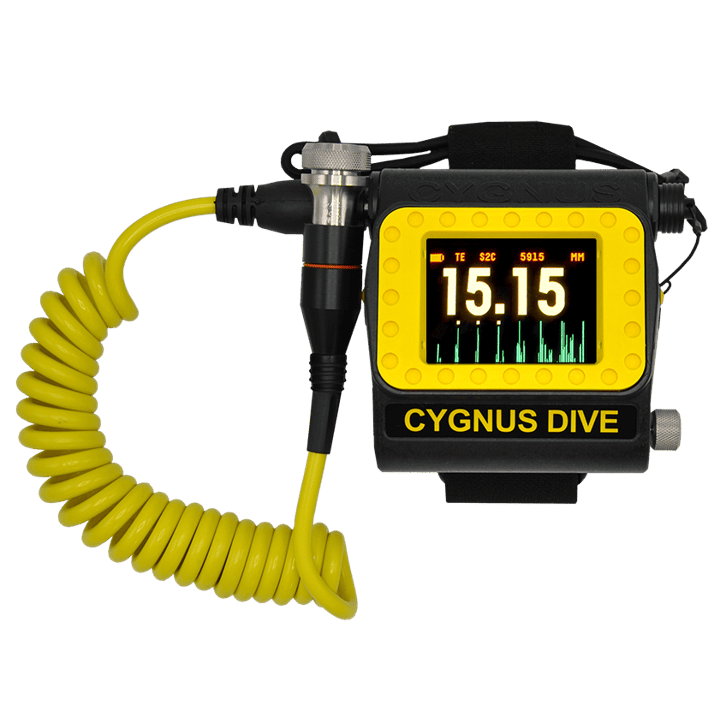

Cygnus DIVE Underwater

Providing an invaluable free hand while performing underwater ultrasonic thickness measurement, the Cygnus DIVE is a ...

More InfoCygnus 4+ General Purpose

A versatile thickness meter used for a wide range of applications, the Cygnus 4+ offers: live A-scan display; sequent...

More InfoCygnus 1 Ex

Designed for taking reliable thickness measurements in all hazardous gas Zones (0, 1, 2), coal mines and combustible ...

More Info