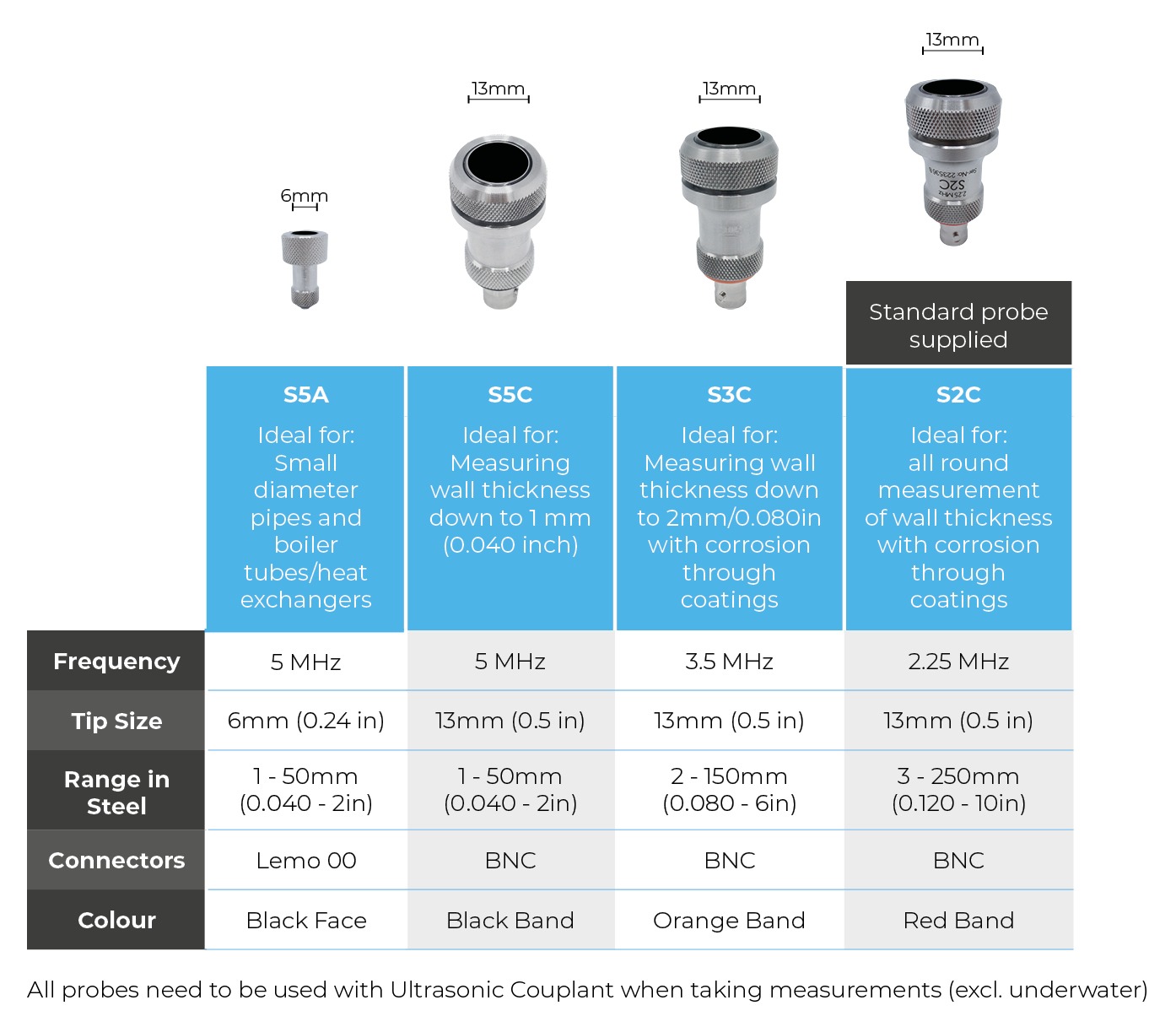

Single Element Ultrasonic Transducers

Single Element transducers are particularly suited to read through and ignore coatings. They are used with our meters in our Multiple-Echo mode. Constructed from high-end stainless steel, they have a soft face that incorporates a replaceable wear membrane. This protects the transducer face ensuring years of reliable, accurate service.

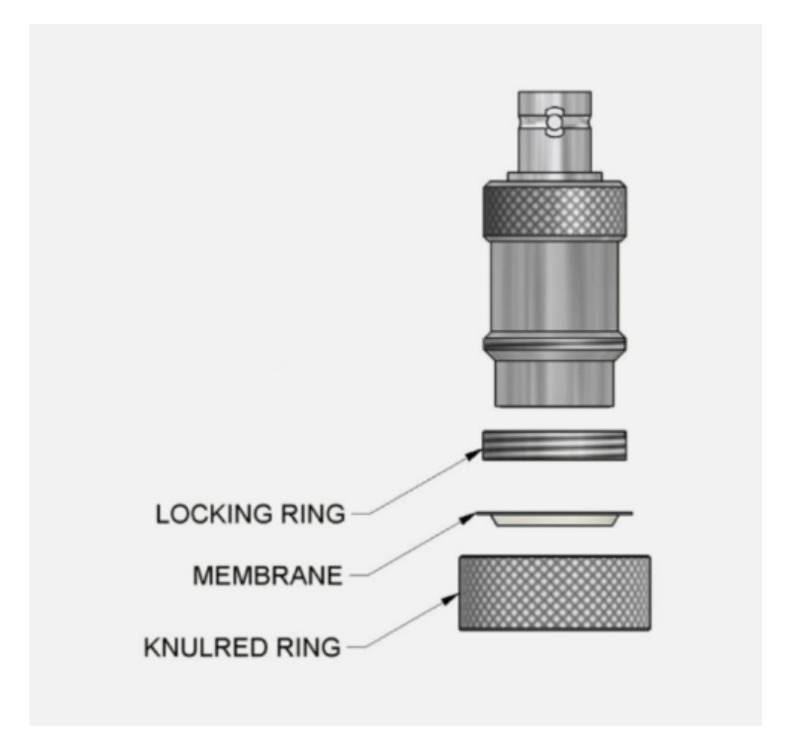

Transducer Membranes

Cygnus single crystal transducers have a protective membrane fitted in front of the transducer face to protect it from wear or damage during use. The membrane is back-filled with a small amount of oil that also helps the transducer face “mould” to surfaces being measured.

The performance of the transducer depends on the condition of the membrane and how well it has been fitted. Cygnus recommends membranes are replaced frequently as a precaution or at the first sign of any scoring, tearing or damage.

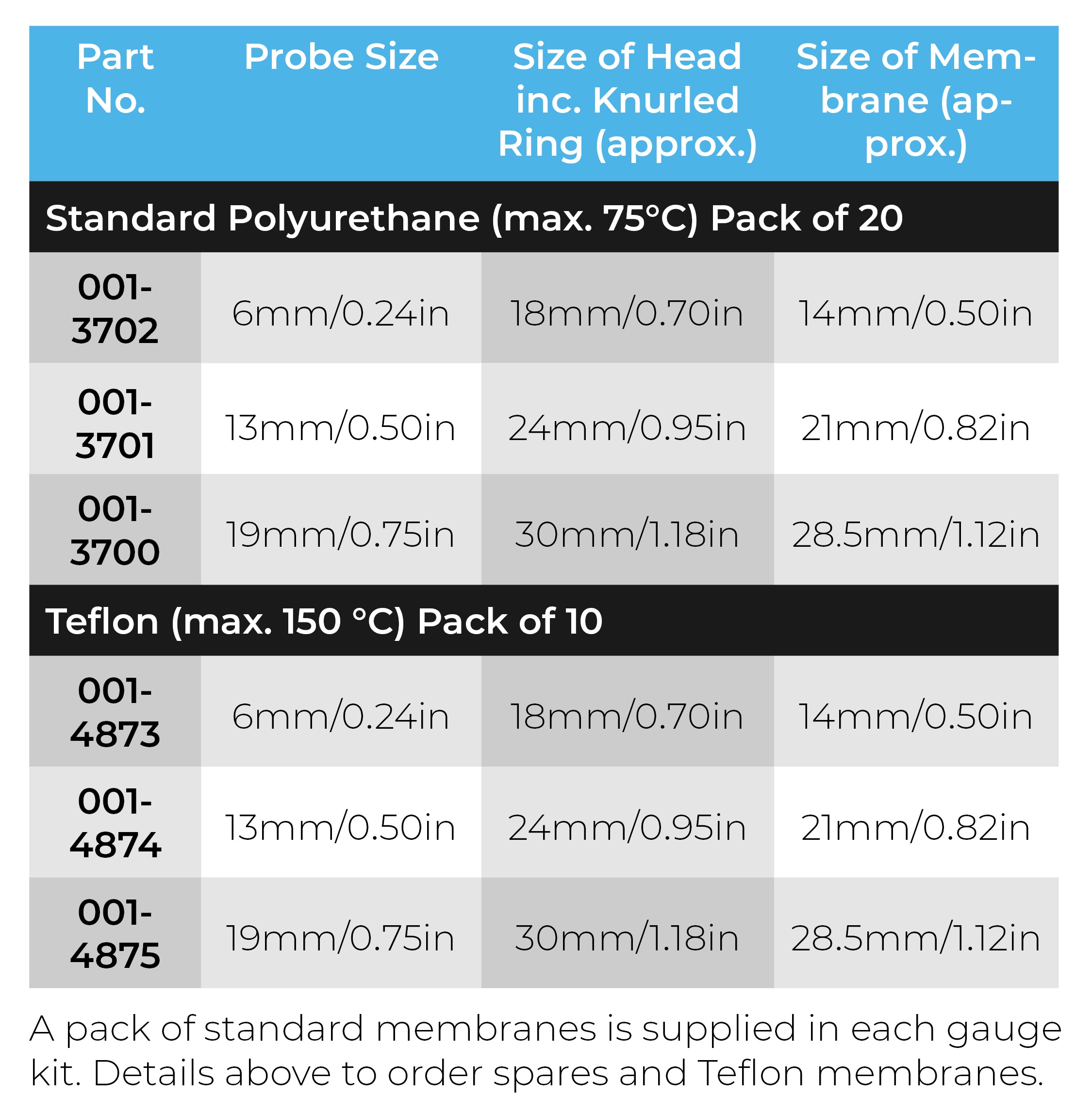

Membranes are available in two materials, the standard Polyurethane membrane is suitable for surface temperatures up to 167°F (75ºC). Also available is a Teflon membrane that is suitable for surface temperatures up to 302°F (150ºC) – with a maximum contact time of 5 seconds.

Membrane Couplant

Membrane couplant (oil) needs to be used between the membrane and the transducer face. This creates a thin layer of oil that allows the ultrasound to pass through.

A bottle of Membrane Couplant is supplied in each thickness gage kit.

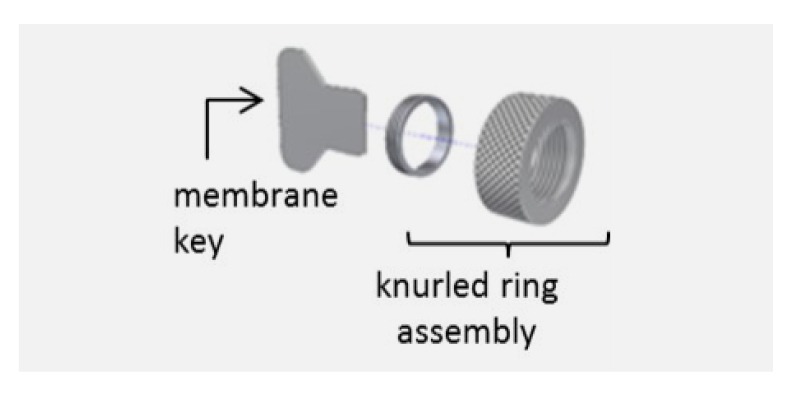

Knurled Rings and Membrane Locking Ring Keys

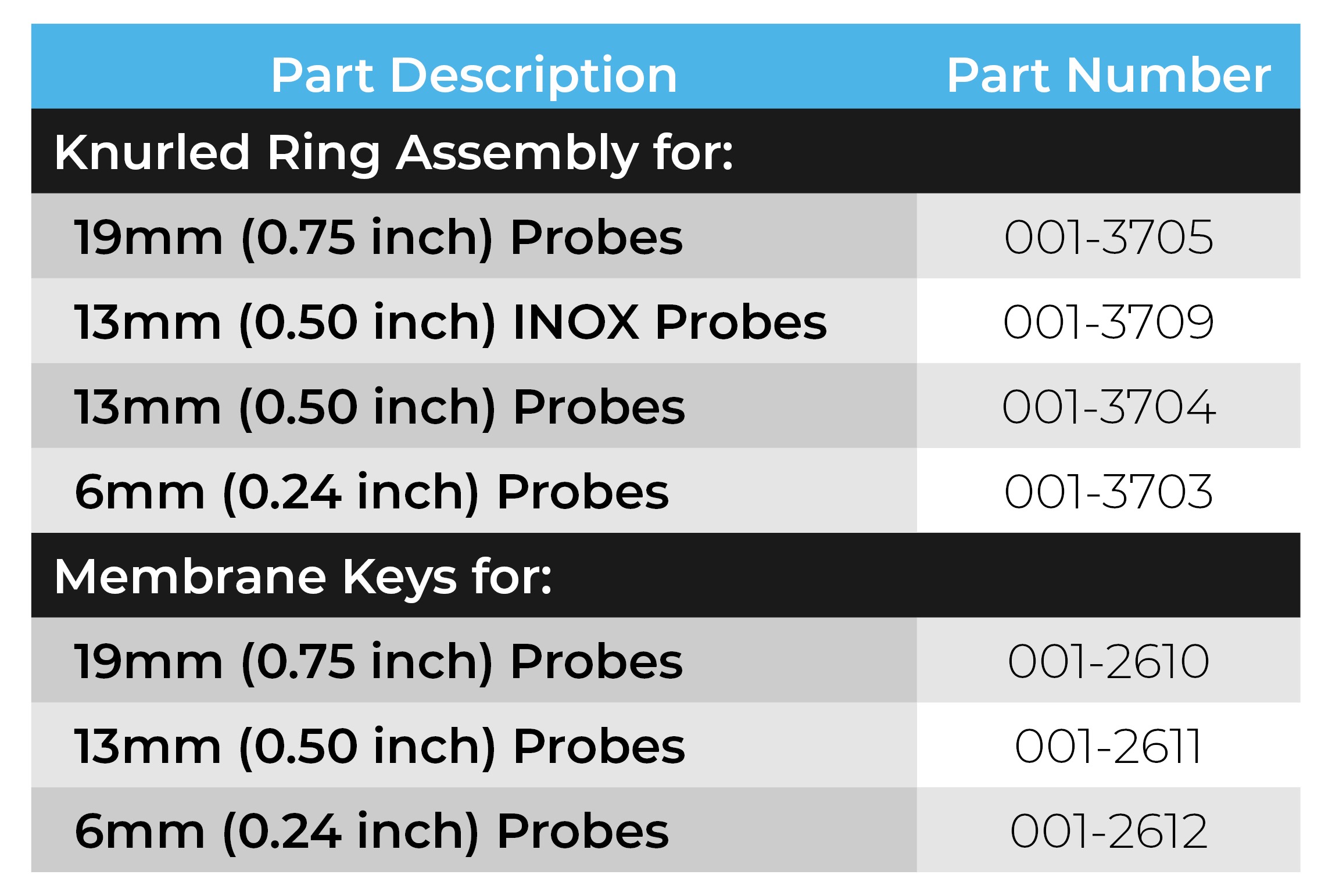

Supplied with every single crystal transducer, a knurled ring holds the membrane in place. A membrane key is used to unscrew and screw in the locking ring in to which the membrane fits.

Transducer Membranes

Knurled Rings and Membrane Locking Ring Keys

Reviews

There are no reviews yet.