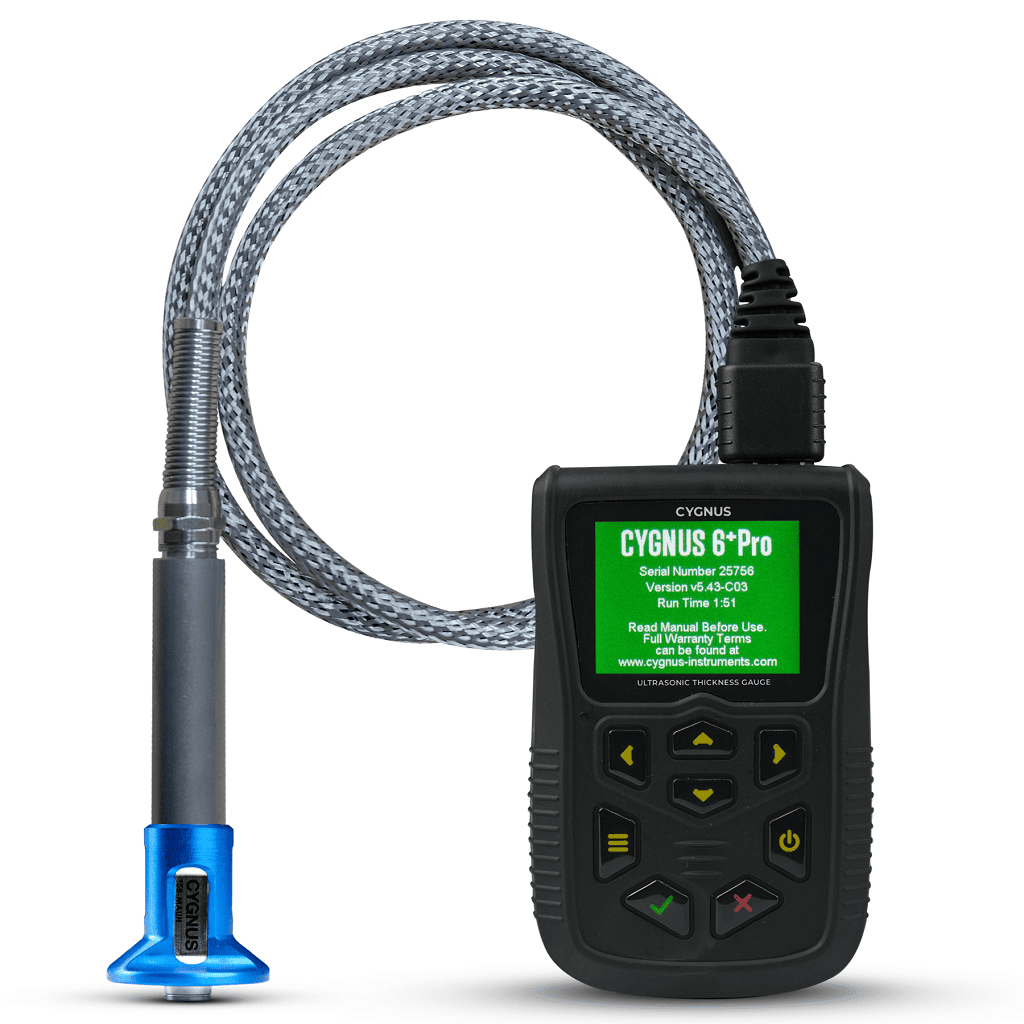

Cygnus 6+ PRO

Ultrasonic Thickness Meter

Key Features of the Cygnus 6+ PRO Meter

- Multiple-Echo mode for accurate, through-coat measurements as specified by Classification Societies

- Echo-Echo and Single-Echo modes for heavily corroded metals with thin (or no) coatings

- Temperature Compensation

- Deep Coat function ignores coatings up to 0.8 inch thick

- Manual and automatic gain control

- Min/max measurement limit functions with visual and vibrate alert

- Uses both single and twin crystal transducers

- One and two point calibration

- Freeze function

- Bluetooth™ for data transfer

- Large front LCD display and an end-mounted LCD display with grayscale setting for bright sunlight

- Safe operation in explosive atmospheres: Class 1, Division 2, Group D locations only, as defined in NFPA 70, Article 500

- Water and dust tight IP67 housing

- Shock and impact proof to US MIL STD 810G.

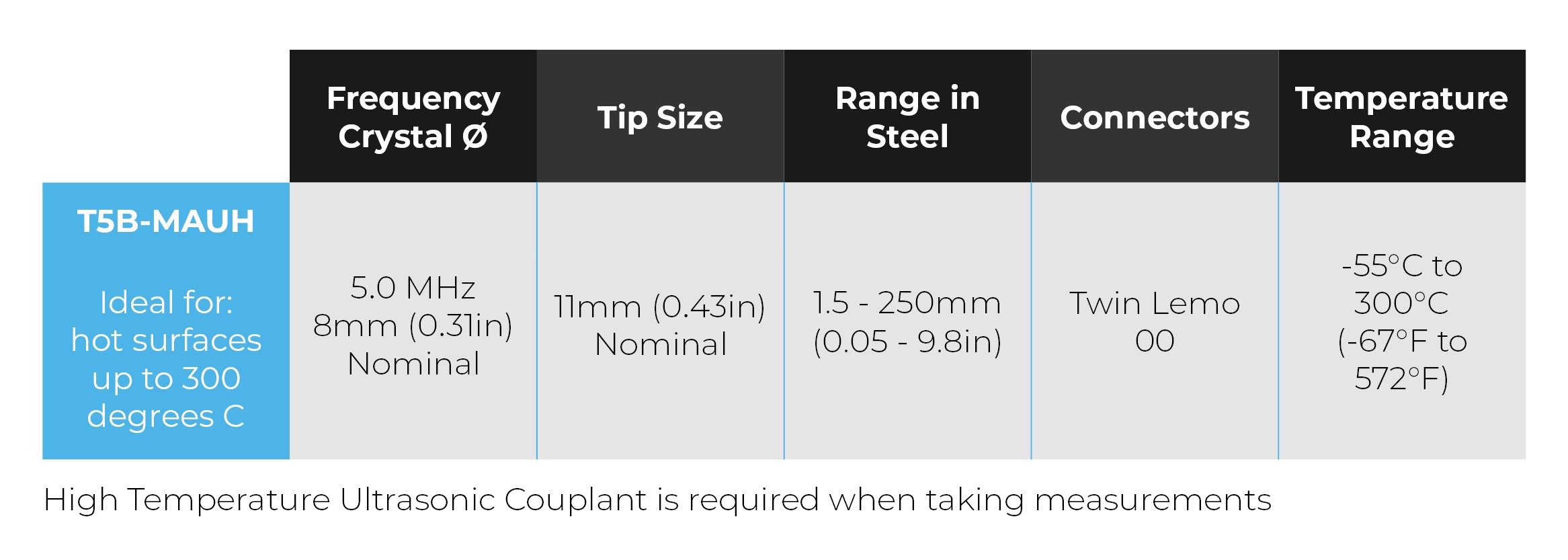

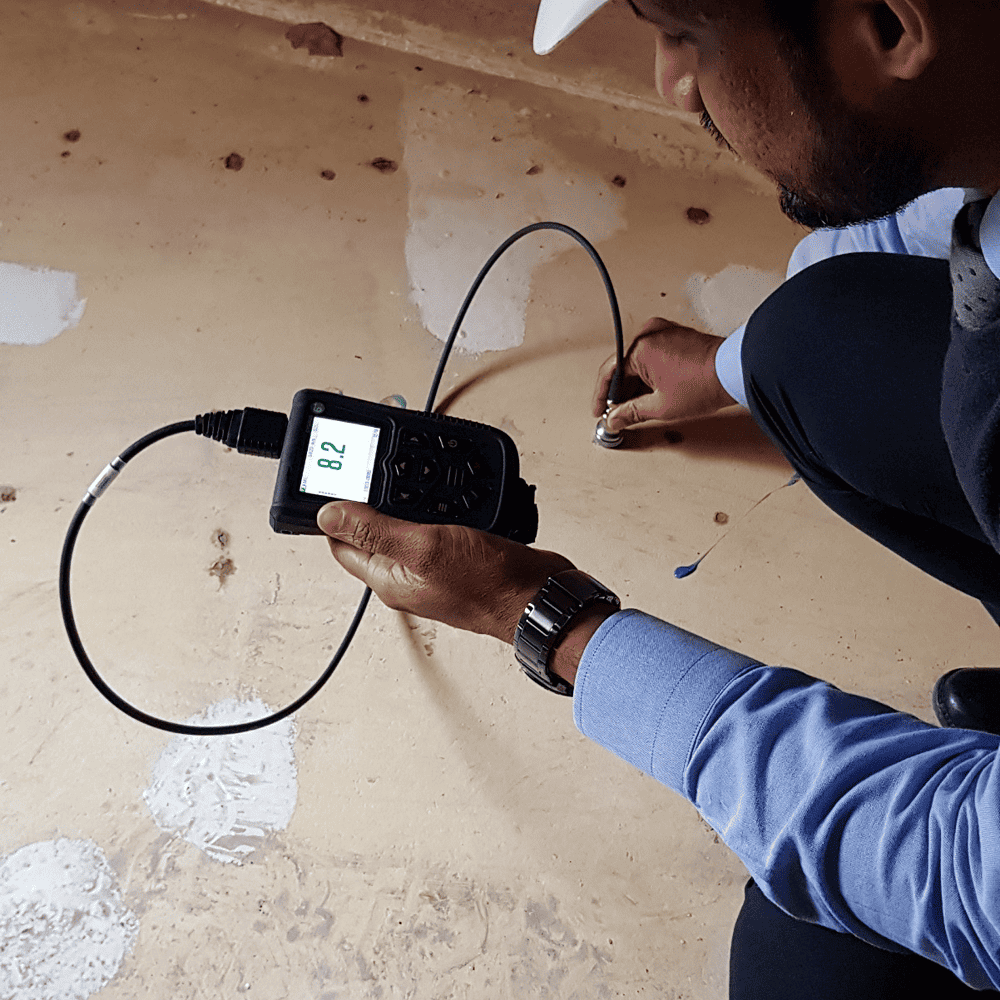

High Temperature Measurement

Using the T5B-MAUH high temperature transducer, measurements can be taken on hot surfaces of up to 572°F.

No cooling period is required – which can reduce inspection time and facilitate more effective measurement.

Optional upgrade to braided cable.

Comprehensive Data Logging

- Linear, 2D grid and template data recording options

- 16 grid patterns available

- ‘Radial points’ can be added to any measurement to further investigate an area of interest or heavy corrosion

- Auto-log feature

- Saves measurements and corresponding wave forms / A-scans

- Eight user-defined text comments to attach to any measurement point

- Records stored on an SD card

- Dedicated CygLink software used to transfer and manage data.

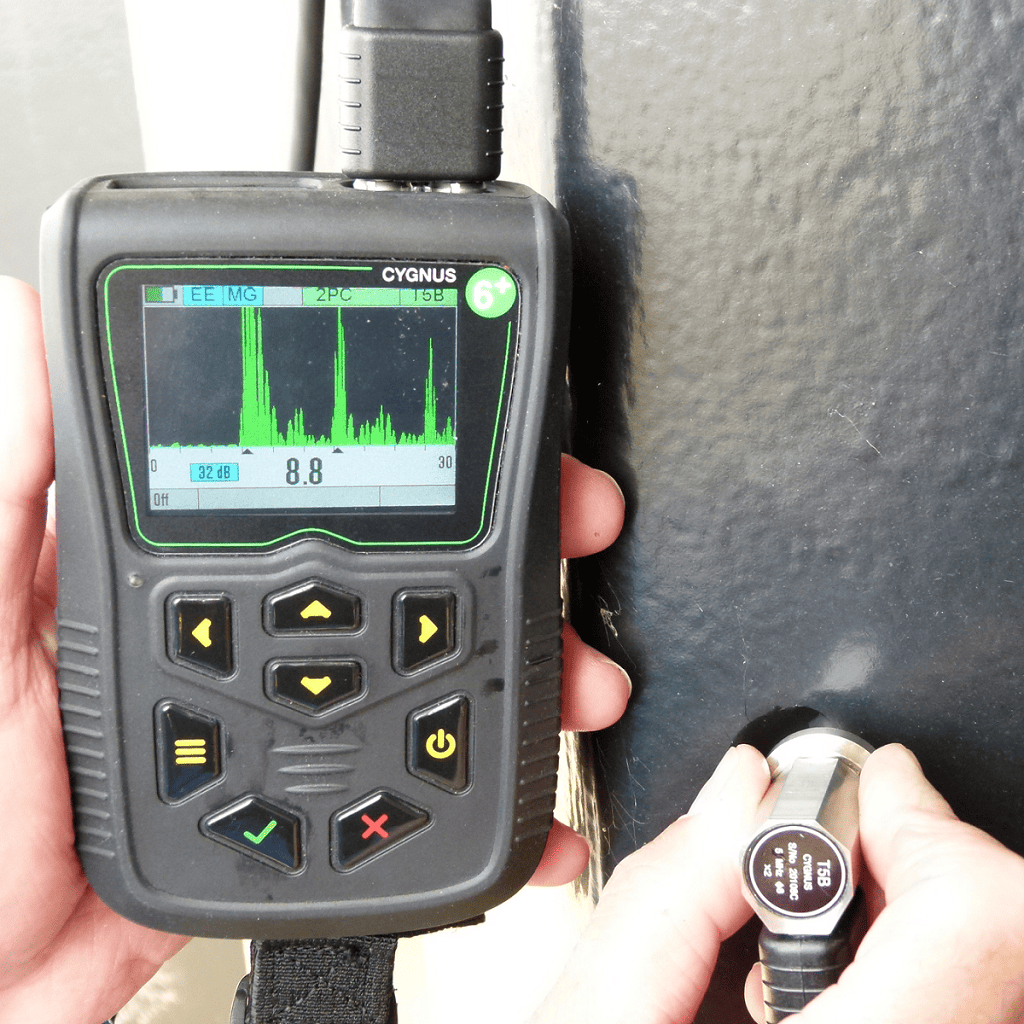

Three Versatile Measuring Modes

- Multiple-Echo mode uses three error checked back wall echoes to provide the most reliable and accurate remaining thickness measurements possible, with no need to remove coatings up to 0.8 inch thick

- Single-Echo mode is ideal for measuring uncoated metals with heavy front and/or back-wall corrosion. Also effective on a range of cast metals, plastics and composites

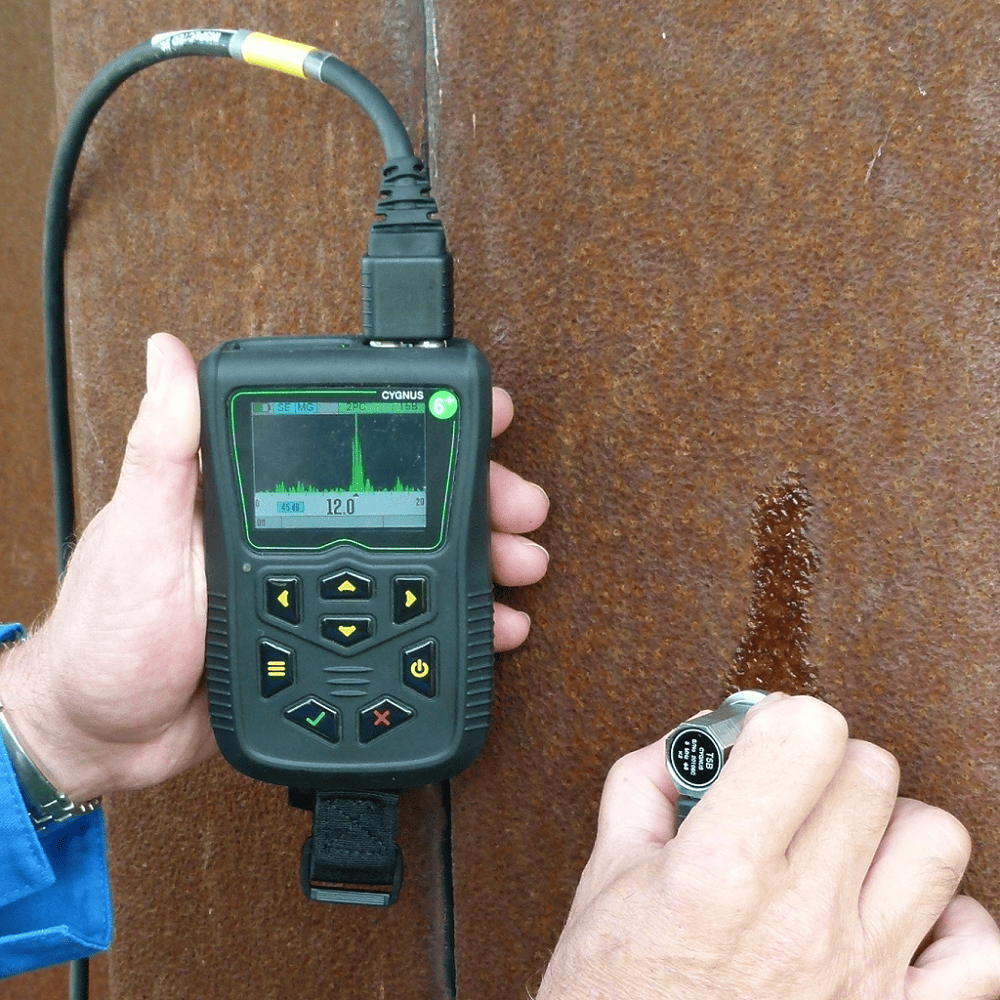

- Echo-Echo mode works best for measuring heavily corroded metals through thin coatings of up to 0.04 inch thick, ideal for measuring painted metals with heavy back wall corrosion.

CygLink Computer Software

CygLink is a Windows® based application used to both transfer and manage data logged records, their corresponding A-scans as well as measurement comments and material velocity tables. The program can generate PDF reports to present to a client and will also export data to Excel. Cyglink also displays A‑scans, allowing for after-the-event and off-site analysis of logged measurements.

The latest version of CygLink software is available to download – from ‘Software Downloads’.

Measurement Stability Indicator (MSI™)

Exclusive to Cygnus, MSI™ ensures stable and therefore reliable measurements are displayed in Echo‑Echo and Single-Echo modes.

Multiple-Echo Ignores Coatings up to 0.8 inch Thick

Measuring Heavily Corroded Metals

Echo-Echo Mode Ignores 0.04 inch Thick Paint

Cygnus Thickness Gage Impact Test

Cygnus Thickness Gage Water Resistance Dunk Test

Cygnus Thickness Gage Water Resistance Hose Test

Cygnus 6+ Dual Display

Large Bright LCD Display

Large LCD Display and Simple Menu Operation

Measuring Uncoated Small Diameter Pipes

Measuring Small Diameter Pipes Through Coatings

A-Scan on Corrosion

B-Scan

| Measuring Modes | Multiple-Echo using 3 echoes to ignore coatings up to 0.8 inch thick Echo-Echo using 2 echoes to ignore coatings up to 0.04 inch thick Single-Echo using 1 echo |

| Materials | Velocities from 0.0390 – 0.3543 in/us |

| Accuracy | ±0.002 inch – in Multiple-Echo measurement mode, when calibrated and measuring the same material as calibrated on ±0.004 inch or 0.1% of thickness measurement whichever is the greatest – in Single-Echo & Echo-Echo measurement modes, when calibrated and measuring the same material as calibrated on |

| Resolution | Multiple-Echo mode – 0.005 inch or 0.002 inch Single-Echo and Echo-Echo modes – 0.005 inch or 0.001 inch |

| Transducer options | Single crystal transducers, Twin crystal transducers and High temperature transducer |

| Measurement Range in Steel | 0.031 – 10 inch depending on selected transducer and configuration, material and temperature |

| Connector | 2 x Lemo 00 |

| Power | 3 x AA / R6 batteries |

| Battery Life | Approx. 10 hours continuous measurement |

| Electronics | Dual channel pulser |

| Display | Front LCD 2.4 inch QVGA: 47 x 37 mm End-mounted LCD: 25.58 x 6.38 mm |

| Size | 3.3 x 5.1 x 1.4 inch |

| Weight | 10.5 oz (inc. batteries) |

| Operating Temp. | 14°F to 122°F |

| Data Logging | 5,000 measurements and A-scans per record Max number records: 100 (soft limit) |

| Computer Software | CygLink allows remote logging and viewing of A-scan graphs Survey and report generation to PDF file Graphic analysis of data and statistical calculations |

| Environmental Rating | IP67 Safe operation in Explosive Atmospheres: Class I, Division 2, Group D Locations only, as defined in the National Fire Protection Association Code (NFPA 70), Article 500. Tested using MIL-STD-810G, Method 511.5, Procedure I MIL STD 810G Method 501.6 (high temp +55°C) MIL STD 810G Method 502.6 (low temp -20°C) MIL STD 810G Method 507.6 (humidity 95%) MIL STD 810G Method 512.6 (immersion 1 metre for 30 mins) |

| Shock and Impact | MIL STD 810G Method 514.7 (vibration) MIL STD 810G Method 516.7 (shock 20g) MIL STD 810G Method 516.7 (transit drop 1.22 m) |

| Standards | Designed for EN 15317 |

| Compliance | CE, UKCA, RoHS |

| Warranty | 3 years on gage and 6 months on transducer |

Basic Gauge Kit

- Cygnus 6+ gauge fitted with hand strap

- Operating manual

- Neck strap

- Accessory pouch, containing; 3 x AA batteries, blue couplant gel

- USB memory stick with CygLink installer

- USB Lead

Kit supplied with Single Element Transducer

- Ultrasonic transducer

- Moulded transducer cable

- 15 mm (or ½ inch) steel test block

- Spare membranes

- Membrane key

- Membrane couplant.

Kit supplied with Twin Element Transducer

- Ultrasonic transducer

- Moulded transducer cable.

| Weight | 5 kg |

| Kit | Cygnus 6+ PRO Standard Kit WITHOUT PROBE (050-6500/5), Cygnus 6+ PRO High Temperture Kit with Probe T5B-MAUH 5MHz Twin Element & Twin Lemo 00 to Microdot Lead (050-6502/5) |

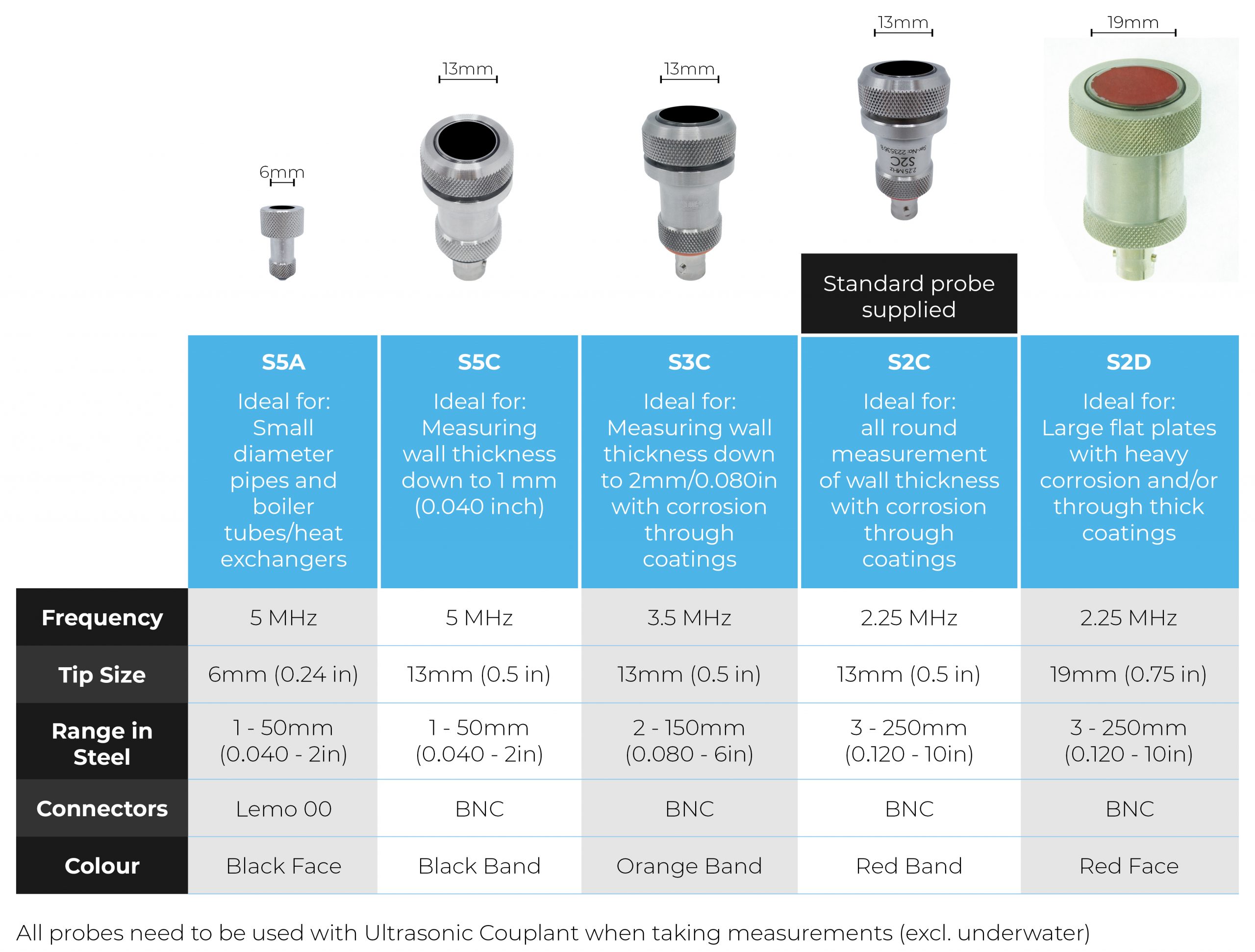

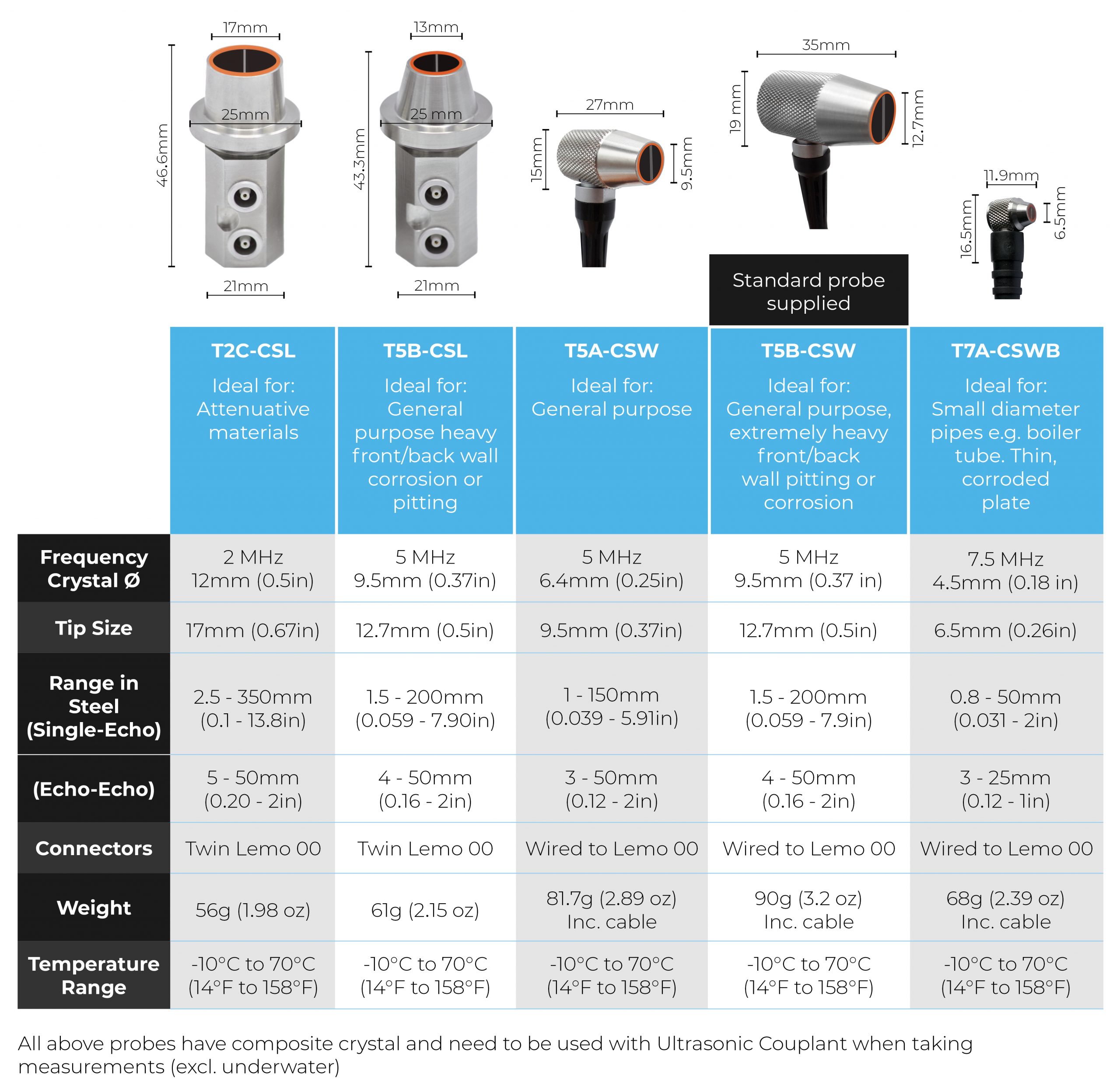

To compliment our ultrasonic thickness gauges we offer a range of ultrasonic transducers . The performance of any ultrasonic thickness gauge relies heavily on the transducer and its suitability to the material being measured. Therefore, selecting the right transducer is vital. All Cygnus’ transducers are made from stainless steel and have a hard wear face or a wear membrane to protect the transducer.

Variety of Cygnus INOX Transducers

- Stainless steel SINGLE CRYSTAL transducers, used in multiple-echo mode, include replaceable membranes for long life, require no zeroing and have a high linear accuracy.

- Stainless steel TWIN CRYSTAL transducers, used in echo-echo and single-echo modes, have improved measurability on extreme back wall corrosion and pitting.

- Transducers for use with the Cygnus 2+, 4, 4+ and 6+ gauges are fitted with a BNC or Lemo 00 connector.

Single Crystal Transducers

Twin Crystal Transducers

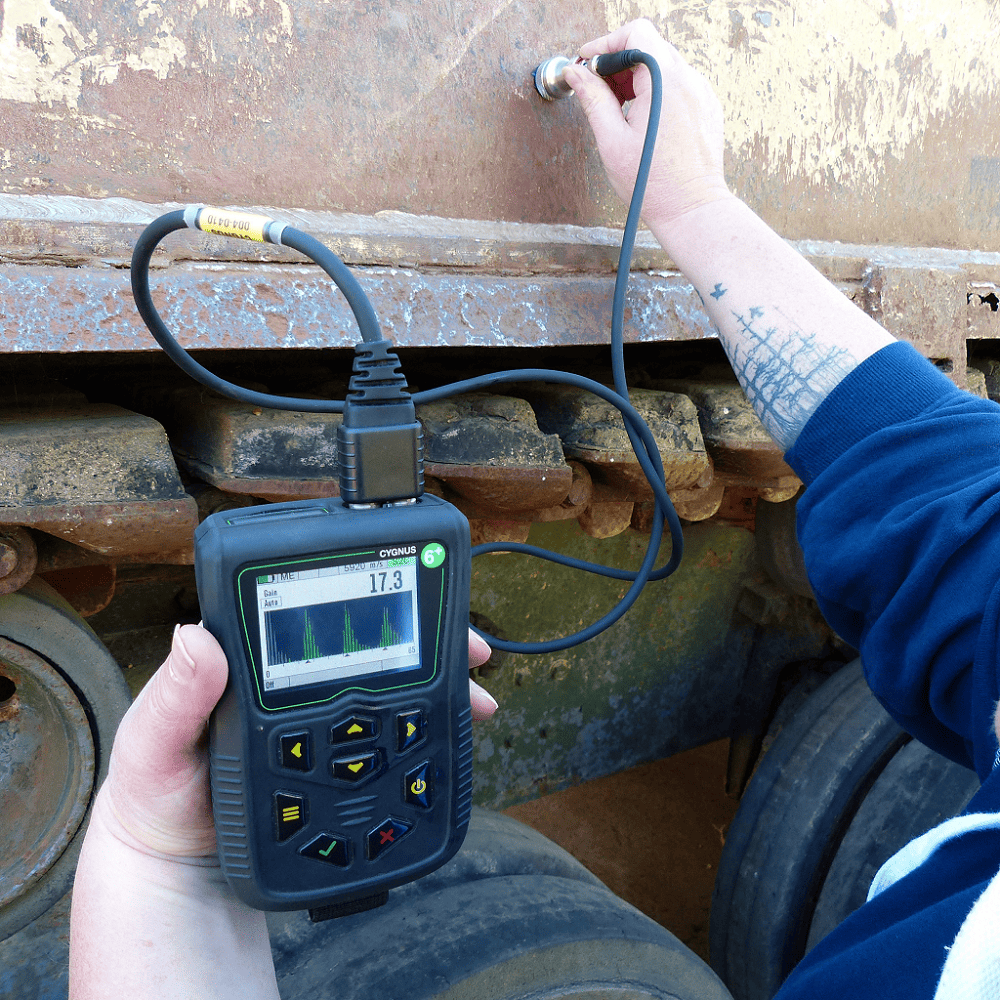

High Temperature Transducer

Twin element ultrasonic transducer designed for high-temperature, in-service thickness measurements and corrosion surveys across oil & gas, refining, energy and process sectors.

- No cooling period required – reducing inspection time and facilitating effective measurement

- For use on hot surfaces up to 572°F

- Measures remaining wall thickness from 0.05 to 9.8 inch – depending on temperature and material.

Cygnus Surface Gage Family Brochure

Cygnus Surface Range Comparison Guide

Cygnus 6+ PRO – Consumables Reorder Form

5 reviews for Cygnus 6+ PRO

Stewart D.

Jul 18, 2016 11:05 AM

I would like to express our appreciation regarding Cygnus’ support during a recent umbilical manufacturing verification project. Your customer service was exemplary and we are impressed by the legibility of the readout on the Mk5 gauge. On appraising Cygnus of the background to our requirement, the equipment was despatched and received the next day. Its ease of use means that we will certainly call upon you for any further such requirements. Thanks for your assistance.

Ricky T.

Mar 27, 2017 11:04 AM

Getting to grips with it, it’s had a little use I think it’s showing about 20hrs on the opening screen. I like the new style and display also like the wrist mount. Not used the data logging yet but I am sure I will. A pleasure to do business with you and I am sure I will be back again in the future.

Agboola O.

Apr 24, 2017 11:07 AM

first time I believed is going to perform well

Blagoja S.

Oct 01, 2019 11:03 AM

We have purchase 4 pcs. of Cygnus 4+ UTG Kit and 1 pcs. of Cygnus 6+ UTG Kit. With these instruments we have check more that 3.000.000 points on coated steel pipe. Results were among expected. We are more than satisfied with equipment.

Mr Hernandez

May 06, 2020 11:06 AM

We tried the gauge on steel components of civil structures and it gives really accurate readings.