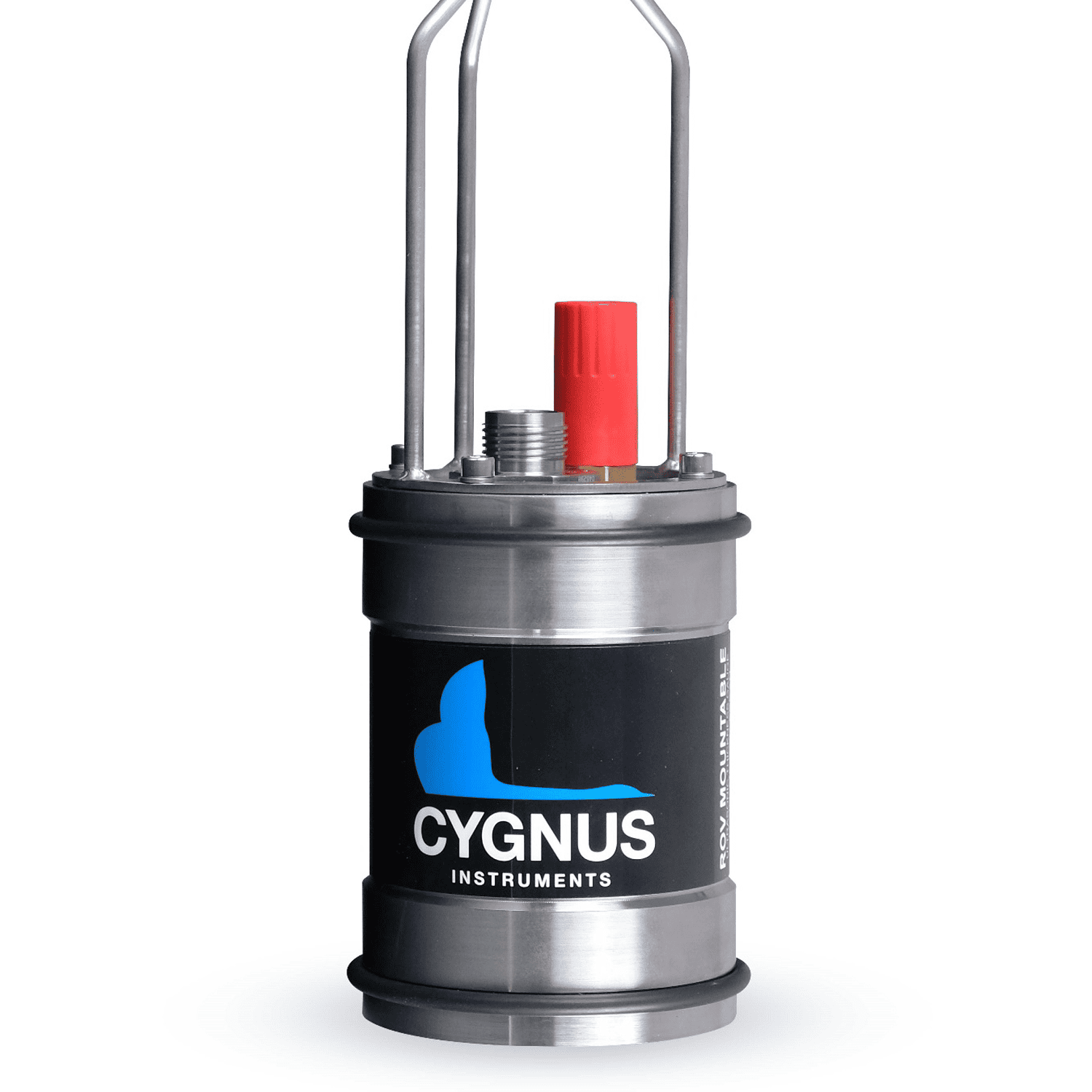

Cygnus ROV UTM

Ultrasonic Thickness Meter

Key Features of the Cygnus ROV UTM Meter

- A-scan / Waveform to assist with measurement verification

- Multiple-Echo and Echo-Echo modes for accurate measurements through coatings up to 0.04 inch

- Single-Echo mode for heavily corroded metals with no coating

- Manual or automatic gain control

- High-performance SD2C transducer fitted with a Hard Rexolite Delay line

- Use the Auto Single-Echo / Echo-Echo / Multiple-Echo measuring mode for best results or set manually

- P50 Transducer Handler cleverly-designed to self-align with pipes from 50 mm diameters to flat surfaces

- Supplied with CygLink software to display and process measurements on a computer at the surface

- Easy calibration and measurement settings via CygLink software at the surface

Benefits of Multiple Echo

- Accepted by all major classification societies

- Measures remaining metal thickness on corroded and coated structures

- All measurements are error checked using 3 return echoes to give repeatable, reliable results

- Saving inspection time and costs

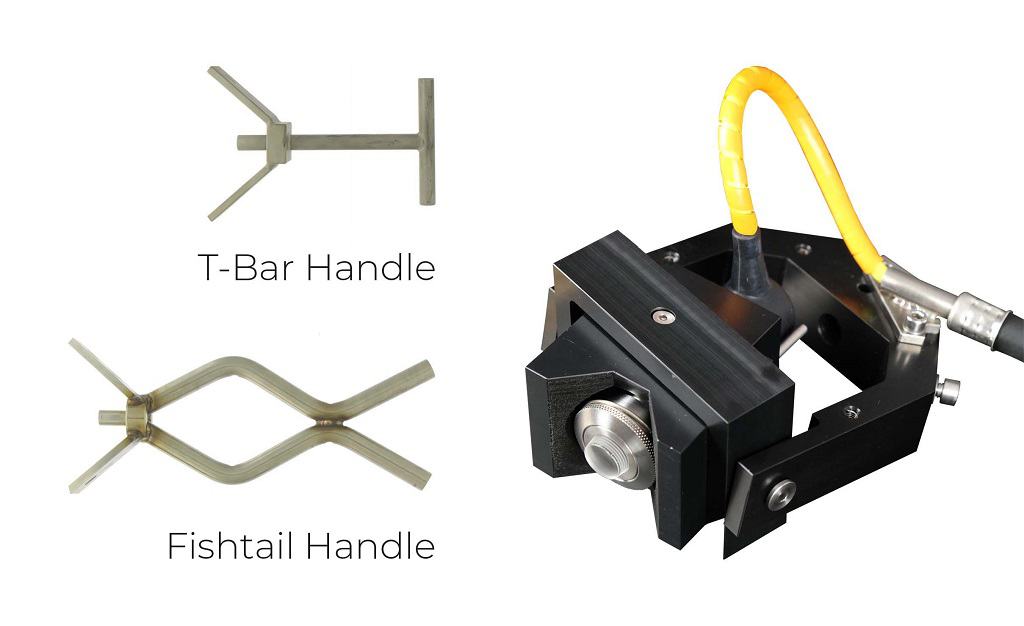

Transducer Handling Solutions

The ‘P50’ Transducer Handler is designed to align the ultrasonic transducer on to straight pipes, from 2 inches in diameter all the way up to up to flat surfaces.

The spring-loaded transducer and v-shaped block allow the transducer to be positioned correctly on a straight pipe and move to accommodate different pipe diameters.

A gimbal allows the transducer to align on to the straight pipe surface when used with a ROV manipulator arm.

The transducer handler can be fitted with a choice of manipulator handles; T Bar or Fishtail.

Cyglink Computer Software

CygLink is a Windows® based application used to both transfer and manage data logged records, their corresponding A-scans as well as measurement comments and material velocity tables. Cyglink can generate PDF reports to present to the client and will also export data to Excel. Cyglink also displays A‑scans, allowing for off-site analysis of logged measurements at a later date.

The latest version of CygLink software is available to download – from ‘Software Downloads’.

| Materials | Sound velocities between 2,000 – 9,000 m/s |

| Measuring Modes | Multiple-Echo using 3 echoes to ignore coatings up to 1 mm thick Echo-Echo using 2 echoes to ignore coatings up to 1 mm thick Single-Echo using 1 echo |

| Accuracy | ±0.1 mm or 0.1% of thickness measurement, whichever is greatest, when calibrated in accordance with Cygnus Instruments calibration procedure |

| Measurement Range in Steel | Multiple Echo: 4 – 20 mm Echo Echo: 4 – 30 mm Single Echo: 4 – 50 mm |

| Measurement Resolution | 0.1 mm |

| Probe Zero | Automatic and manual selectable |

| Power | 12 – 24 V supply input @ 60mA (average) @ 200mA (maximum) |

| Size | 105 x 110 x 35 mm |

| Weight in Air | Gage body 3.7 kg max. |

| Operating Temp. | -10°C to 50°C |

| Environmental Rating | IP68 rated to 3,000 m |

| Communication | RS-232 |

| Computer Software | CygLink allows remote data logging and viewing of A-scan graphs. Survey and report generation to PDF file. Graphic analysis of data. Designed for Windows 10 and above. |

| Environmental | CE, UKCA, RoHS |

| Warranty | 3 years on meter and 6 months on transducer |

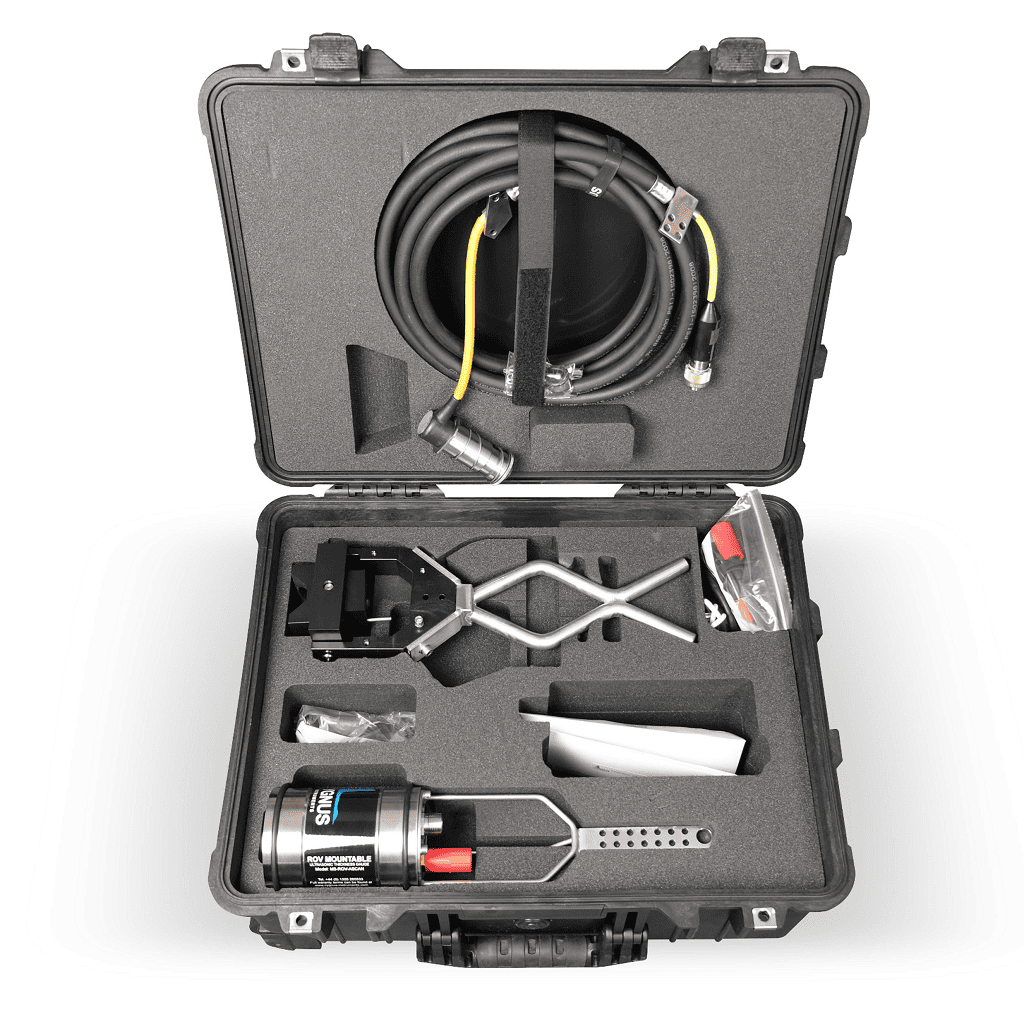

The Cygnus ROV UTM gage is supplied as a complete kit in a transportation case and includes:

- M5-ROV-ASCAN subsea instrumentation unit

- SD2C-DAW 2.25 MHz single element delay line transducer with cable and connector, fitted in a P50 transducer handler

- Patch cable for wiring the M5-ROV-ASCAN to the ROV, 0.6 m

- Test lead – RS-232 to USB

- Test block 15 mm thick in 1080 mild steel

- USB flash drive with CygLink software and documentation

- A calibration certificate

- Silicon grease for lubricating connectors and O-rings.

| Weight | 5 kg |

The Cygnus ROV UTM meter uses a high-performance SD2C transducer that is fitted with a Hard Rexolite Delay line.

Reviews

There are no reviews yet.